Repair of utilities located under highways is necessary due to increasing traffic load and wear of pipes. Although, excavated highway is a serious problem for freight traffic and passengers’ transportation. For prevention of traffic jams it is recommended to apply trenchless rehabilitation of pipelines. It is a special type of technologies for cleaning and rehabilitation of a section of a pipeline without need to excavate utilities. So-called “trenchless” method of rehabilitation of an operating pipeline which is popular in Europe, now becomes popular in our country.

Repair and maintenance of engineering networks

We apply trenchless technologies for cleaning and maintenance of pipelines.

Up-to-date technologies for cleaning of pipelines

15 years of experience in the sphere of engineering networks

A high percentage of wear of pipelines is the result of Soviet history when the state performed a great amount of utilities construction works but no one was responsible for quality and long-term operation of utilities. Actual life term of metallic pipelines is over, and utilities operate till the next burst. More than half of the utilities’ length is corroded, and every year there are identified new defects and bursts. Another half is in pre-emergency condition, that is why the work for rehabilitation and repair of pipelines is executed continuously. According to international experience, the best solution is application of trenchless rehabilitation or repair of pipelines.

Stages of rehabilitation works

In order to get full information of condition of pipelines there is used CCTV-inspection method (videodignostics) in addition to cleaning.

CCTV-inspection is a method of research of engineering systems with use of video-equipment. This research is performed with use of colour video-camera fixed by a special flexible cable. It is inserted in the pipe section under research, the image is transferred to LED-display. High resolution of camera and application of lighting allow identification of any kind of defects – from blockage and rust points to small cracks, disconnections and offsets.

Thanks to CCTV-inspection it is possible to save client’s funds as after inspection sound sections of pipeline are eliminated from schedule rehabilitation list. Use of video-diagnostics equipment allows reaching and timely elimination of blockages or leaks in pipelines without excavation.

CCTV-inspection of pipelines is also used for precise determination of length of a pipeline, level of damage, determination of illegal tapping and sources of damages.

Moreover, if cleaning or rehabilitation works are performed by our professionals, CCTV-inspection of pipelines is obligatory performed after completion of cleaning or rehabilitation in order to ensure absence of defects. CCTV-inspection is also performed at acceptance of new pipelines when it is necessary to estimate reliability of a new pipeline.

CCTV-inspection allows identification of foreign objects and sand in pipes, examination of quality of connections. The client may review the results of inspection in the process of inspection or later, when the results will be presented to him in electronic format (CD-disc).

Nowadays cleaning of pipelines is one of the most important moments for effective operation of utilities system. Such utilities systems include, first of all, pipelines of any purpose. Proper operation and accident-free condition are the key to success and convenient living of all inhabitants of the building. It is much better to avoid the potential problem than deal with its consequences.

We perform hydrodynamic cleaning which is more professional in comparison with other types of cleaning. Such type of cleaning is performed with use of special cleaning machinery based on principle of cleaning with high pressure water jet. Such high pressure water jet damages and washes out the deposits and sediments on pipe walls. It is preferable to perform at the same time two types of cleaning: both mechanical and hydrodynamic one in order to clean and wash out the sediments from the pipeline. Moreover, modern hydrodynamic cleaning mechanisms can change water head level and heat the water which improves the quality of cleaning.

Technologies

CIPP – Cured-In-Place Pipes

Rehabilitation of pipelines with help of pipes cured in place. PHOENIX™

This method is used for rehabilitation of pipelines of any form of section (round, oval, rectangular, etc.) for drinking water, technical water supply and sewage and household sewage. Moreover, this method is used for rehabilitation of siphons. Technically this method is simple: a liner made of several layers of polyester fiber is impregnated with epoxy resins, afterwards it is installed in an old pipe without excavation, and polymerized (cured) in place which forms a new strong pipe closely fitting into the old pipeline.

SPR — Spiral wound technologies

EXPANDAтм

EXPANDAтм lining technology is a unique process aimed at improvement of effectiveness, reliability and safety of sewage, storm sewage and drain pipelines. Available diameters of new EXPANDAтм pipes are 150 mm to 750 mm.

Winding machine is an important element of winding process, this machine is placed and fixed in the start manhole. At the first stage a new pipe has a smaller diameter in comparison with the host pipe. Winding process is registered and controlled by an operator through a computerized machine. At the second stage a new pipe is expanded achieving close fit to the walls of the host pipe.

The expansion is performed through damage of the initial lock by a steel wire installed between profile locks during winding. The initial lock contains slow-curing sealing material supporting expansion process functioning as lubricant.

Expansion is performed till there is achieved close fit to the walls of the old pipe which leads to minimization of diameter loss.

A new pipe has perfect flow characteristics and high level of water tightness and durability.

Advantages of EXPANDAтм technology :

- Winding of a new pipe at current flow.

- Sufficient bearing capacity of the PVC strip.

- A new liner is strong and light.

- Close fit to the host pipe.

- Diameter of 150 mm to 750 mm with use of only 5 types of profiles.

- Made of PVC-pipes grade.

- May be applied for gravity sewage pipelines and drainage pipelines.

- Fast installation with minimum interference in social processes.

- Short preparation period.

- Access shafts are used, no need in soil excavation.

- No need to store new pipes nearby the work site.

- Small-size auxiliary vehicles causing no traffic jams.

- Safe execution of works.

- Works can be executed even at presence of small current flow in the host pipe.

- Installation process can be implemented through almost inacceptable access chambers by using auxiliary vehicles and equipment.

ROTALOCтм

ROTALOCтм system is 100% trenchless technology for non-pressure systems and is used for drain and sewer pipelines with round shape and diameter of 800 to 1800 mm.

ROTALOCтм technology is used for rehabilitation of hydraulic efficiency, reliability and integrity of worn sewer, storm water pipes and culverts made of brick, concrete, fiberglass or corrugated material. Rotaloc pipes are installed from manholes and inspection shafts. A new pipe is gradually wound from one continuous strip of PVC profile by Rotaloc machine.

The machine connects the edges of profile coils as the a new pipe moves in the old pipe forming an integral pipe. Winding machine may change diameter as the pipe moves in the old pipe. The winding process stops when a new pipe reaches the end of the pipeline section to rehabilitate.

A new pipe has perfect characteristics and high level of water tightness and durability. Winding process is registered and controlled by computerized machine.

Advantages of ROTALOCтм:

- Winding is possible at presence of current flow.

- Sufficient bearing capacity of the PVC strip.

- May be applied for gravity sewage collectors, storm water drains and drainage pipelines.

- Self-contained solution

- Close-fit new pipe

- Diameter of 750 mm to 1800 mm

- Standard size of an access manhole

- High efficiency

- Compactness

- Certificates DIBt (Germany) and WRc (the Great Britain)

Cured-in-place pipes (CIPP) with UV-light

Rehabilitation of pipelines using method of curing by UV-light. This method belongs to cured-in-place pipes (CIPP) technologies. According to this technology, a preliminary cured liner is pulled through the host pipe and is cured after heating by UV-lamps. Advantages of this technology: fast installation, fast curing. Application of strong fiber glass liner provides high bearing capacity of the new pipe.

Advantages of the technology:

- seamless design;

- high-quality materials (films, resins, fiberglass);

- storage at warehouses during few months;

- compact work site;

- environmentally friendly technology, less energy-consuming technology.

Горизонтальное направленное бурение

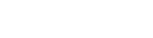

Horizontal Directional Drilling (HDD)

Horizontal Directional Drilling (HDD) technology is used for construction of new engineering networks and repair of worn utilities. Trenchless technologies (lining under a road, HDD lining or inclined drilling) allow lining of new pipes of steel or polyethylene. HDD technology allows lining of pipes without excavation. This technology is popular for installation of pipelines across the inhabited areas, under railway roads, highways, rivers, etc. It is applied for rehabilitation of pipelines with diameter of 150 mm to 1200 mm. Advantages of this method are its high speed and reliability.

Advantages:

- High speed of installation of new pipes. In case of use of trench method instead of HDD method, it will take much more time to complete the works;

- Expansion of season range of works (trenchless installation of pipes is possible at any season);

- Reduction of estimation value of construction works due to significant reduction of work completion period, expenses for additional workers and drilling machinery;

- Minimization of expenses for power supply of drilling complexes due to total automation and economic efficiency of such complexes;

- Absence of expenses for rehabilitation of damaged areas of highways and railways, amenity plantings and objects of urban infrastructure;

- Reduction of operational expenses for examination and reconnection of utilities during operation;

- Absence of damage to agricultural areas and forests;

- Minimization of adverse effect on living conditions of population in the work area;

- Preservation of natural landscape and ecological balance at work area, exclusion of industrial influence on flora and fauna, stream bank erosion and river bottom sediments

Санация методом разрушения

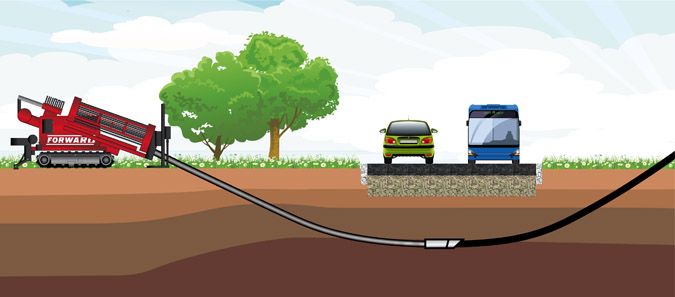

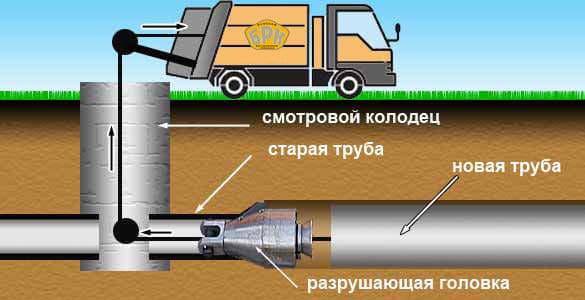

Old pipe destruction technology

Destruction method is widely used for replacement of cast iron, steel, reinforced concrete and other types of pipelines by polyethylene ones which are almost perpetual for sewage and heating pipes.

Main advantages of this technology:

- No need in excavation

- A new pipe is installed inside the host pipe

- Diameter available – up to 1200 mm

- Quick installation of a new pipe

- No vibration

- Increase of pipeline’s transmission capability is possible

Contact details

Address

Republic of Kazakhstan 010000, Nur-Sultan city,

B.Momyshuly avenue 4